What is asthma?

Asthma is a serious health condition that affects the lungs. Thousands of people in the UK and Ireland face the challenges of this disease every day.

There are many different types of asthma and include:

- allergic

- non-allergic

- occupational

Studies estimate that anywhere between *9-15% of all adult asthma cases can be linked to work, (*Source: Work-related asthma statistics, 2023)

Symptoms include:

- wheezing

- coughing

- chest tightness

- severe shortness of breath that can stop you from doing the simplest tasks

Some sufferers may be unable to work due to their condition and in rare cases, an extreme attack can prove fatal.

Symptoms may develop shortly after exposure to a substance which can cause asthma (also known as respiratory sensitisers, allergens, or asthmagens), or can appear several hours later, possibly at night. This can make the link with exposure to a substance (asthmagen), i.e. the cause, in the workplace unclear.

Other associated conditions include:

- rhinitis (sneezing/runny nose)

- conjunctivitis (itchy and inflamed red eyes)

Occupational asthma

Occupational asthma can be caused in a workplace simply by breathing in certain dusts, gases, fumes and vapours that can damage your lungs.

Occupational asthma is an allergic reaction that can occur in some people when they are exposed to substances in the workplace, for example:

- dust from flour/grain

- wood dust

- isocyanates,

- animal fur/feathers

Asthmagens can be present in many industries which involve the following processes:

- baking

- vehicle spray painting

- soldering

- woodworking

- working in the healthcare sector

- working with Laboratory animals

- farming

- engineering work

- welding

Please note that this list is not exhaustive and asthmagens are common across many industries. It is important that any asthmagens present within the workplace are identified, and exposure prevented or adequately controlled.

Substances known to cause occupational asthma

Welding fume

Welding fume is produced when metals are heated above their melting point, vaporise and condense into fumes and this is associated with occupational asthma. Stainless steel welding fume ingredients of chromium and nickel are capable of causing occupational asthma, these are known as asthmagens.

Isocyanates

Isocyanates are highly reactive chemicals used in the manufacture of polyurethane products, for example flexible and rigid foam, fibre, coatings, paints, lacquers and varnishes, expanding foam and are respiratory sensitisers.

Metalworking fluids

Exposure to metalworking fluids can cause; irritation of the skin/dermatitis, occupational asthma, bronchitis, irritation of the upper respiratory tract/breathing difficulties.

Flour dust

Flour dust is a hazardous substance as defined under the Control of Substances Hazardous to Health Regulations (NI) 2003 (COSHH NI). Flour dust and enzymes containing additives such as amylase are asthmagens.

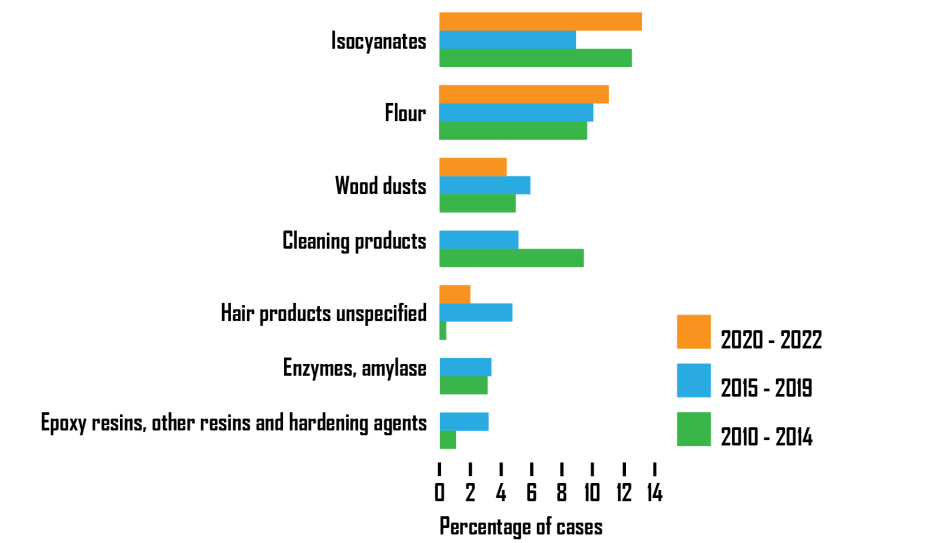

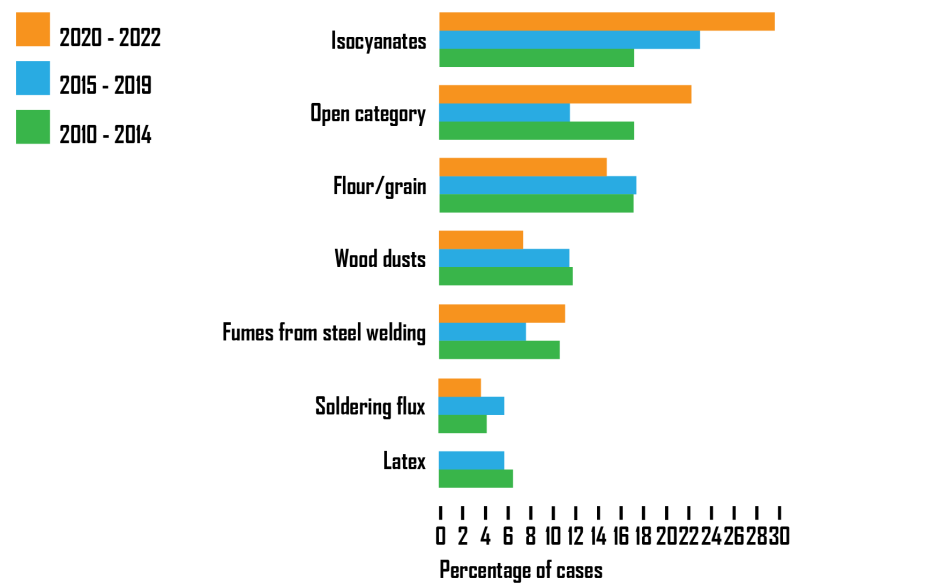

The diagrams below detail a list of the most common agents which can cause occupational asthma:

**Source - HSE Work-related asthma statistics, 2023.

HSE (GB) provide a more detailed list of substances that can cause occupational asthma at the following link:

Health effects

Respiratory sensitisers (or asthmagens) can cause a change in people's airways, known as the 'hypersensitive state'.

Not everyone who becomes sensitised will develop asthma, but once the lungs become hypersensitive, further exposure to the substance, even at quite low levels, may trigger an attack.

In some cases, the person may not be able to continue working in the same environment, resulting in the need for alternative work to be found, if feasible, but may result to loss of employment depending on the circumstances and the associated health risks. i.e. “A life changing condition’’.

Asthma UK developed a charter with guidance from HSE (GB) Asthma at work - Your charter which can be found at the following link:

Controlling the risk

When a substance or substances meets the definition of a ‘substance hazardous to health’ under the Control of Substances Hazardous to Health Regulations (NI) 2003 (COSHH NI), the employer is required, by law, to control exposures to such hazardous substances in order to protect employees' health.

Respiratory sensitisers are considered substances hazardous to health and exposure must be reduced to as low as is reasonably practicable (ALARP).

The Health and Safety Executive’s (HSE (GB)) publication Control of substances hazardous to health (COSHH). The Control of Substances Hazardous to Health Regulations 2002 (as amended). Approved Code of Practice and guidance L5 provides detailed guidance on how to comply with the law.

A full risk assessment should be made prior to using any substance or process to determine whether any substances hazardous to health, including asthmagens, are present or are likely to be generated by the process for example fine sanding of some woods leading to airborne fine dusts etc. or paint spraying with isocyanates, handling animals etc.

Employers must implement the necessary control measures to protect their employees in the following order of priority:

- remove the respiratory sensitiser from the process completely - if this is not possible then consider if it can be substituted with a less hazardous form, for example low-dust flour

- design and operate processes and activities to minimise emission, release and spread of substances hazardous to health

- take into account all relevant routes of exposure - inhalation, skin absorption and ingestion - when developing control measures

- control exposure by measures that are proportionate to the health risk

- choose the most effective and reliable control options which minimise the escape and spread of substances hazardous to health

- where adequate control of exposure cannot be achieved by other means, provide, in combination with other control measures including suitable personal protective equipment (PPE) or respiratory protective equipment (RPE)

- check and review regularly all elements of control measures for their continuing effectiveness

- instruct and train all employees on the hazards and risks from the substances with which they work, and the use of control measures developed to minimise the risks

- ensure that the introduction of control measures does not increase the overall risk to health and safety

HSE (GB) have developed a set of tools designed to assist business in managing the risks, known as COSHH Essentials - COSHH e-tool:

Employers

There are many things you can do as an employer to reduce the risk of occupational asthma in your workplace.

- assess the risks

- apply The Hierarchy of Control:

- elimination - physically remove the hazard

- substitution - replace the hazard with something less hazardous

- engineering controls - isolate people from the hazard

- administrative controls - change the way people work

- PPE /RPE- protect the worker with personal protective equipment

Employees

The key messages for workers are:

- avoid breathing in and direct handling of respiratory sensitisers

- ask your employer if the necessary controls are in place and working

- PPE /RPE must be supplied and maintained free of charge by the employer

- employees must cooperate fully with the employer - this includes attending health surveillance appointments, if necessary

PPE and RPE

PPE and RPE are often considered as the first line of defence, but they should be regarded as the last resort to protect against risks to health.

PPE and RPE is only effective if worn and used properly. Poorly used PPE and RPE can be worse than not using any RPE and PPE, providing workers with a false sense of security.

Issues with RPE include:

- poor fit

- not face fit tested

- worn with stubble or beards (making and effective seal impossible)

- wrong specification for the hazard

- uncomfortable if worn for long periods

- not looked after, or stored properly, becoming damaged or contaminated

Health surveillance

Health surveillance means regularly looking for early signs of work-related ill health and putting procedures in place to achieve this.

The purpose of health surveillance is to monitor and protect the health of individual employees. Collecting simple information may lead to early detection of ill health caused by work and identify the need for improved control measures.

All employees exposed, or likely to be exposed to an asthmagen should receive suitable health surveillance.

The specific requirements are set out in COSHH NI regulations and might involve examinations by a doctor or specialised nurse.

HSE (GB) has produced simple guidance on what health surveillance is required in COSHH Essentials.

Resources

- Control of Substances Hazardous to Health: Approved Code of Practice and guidance (L5) - (hse.gov.uk)

- EH40/2005 Workplace exposure limits - (hse.gov.uk)

- Health surveillance for occupational asthma (G402) - (hse.gov.uk)

- Appointed doctors

- COSHH (NI): A Brief Guide to the Regulations

- Flour Dust

- Isocyanates

- Metalworking fluids

- Motor vehicle repair

- Welding Fume

- Woodworking

- Woodworking and health

- Woodworking safety information sheet

Key legislation

- Control of Substances Hazardous to Health Regulations (Northern Ireland) 2003 - (legislation.gov.uk)